CNC Machining

CNC Machining Services

Innovative Manufacturing and Design’s superior machinists specialize in making parts using CNC machining. We invest in the latest technology and CNC machining centers that expand our capabilities to:

- CNC Turning

- CNC Vertical Milling

- 4-Axis Milling

- 5-Axis Milling

The Highest Quality CNC Machining

Innovative Manufacturing and Design dedicates to the continuous improvement of our processes, so we remain the standard in CNC machining. When you work with us, we guarantee state-of-the-art innovation, unsurpassed execution, and the highest level of precision in the industry!

CNC Turning Services

Innovative Manufacturing and Design offers the highest standard in CNC lathe machining and turning. Our expert CNC programmers and machinists deliver unmatched accuracy and precision.

Our CNC turning centers allow for a wide range of complexities, sizes, and material types. CNC turning is a manufacturing process where the material is held in a chuck and rotated while a tool removes excess material to create a desired shape.

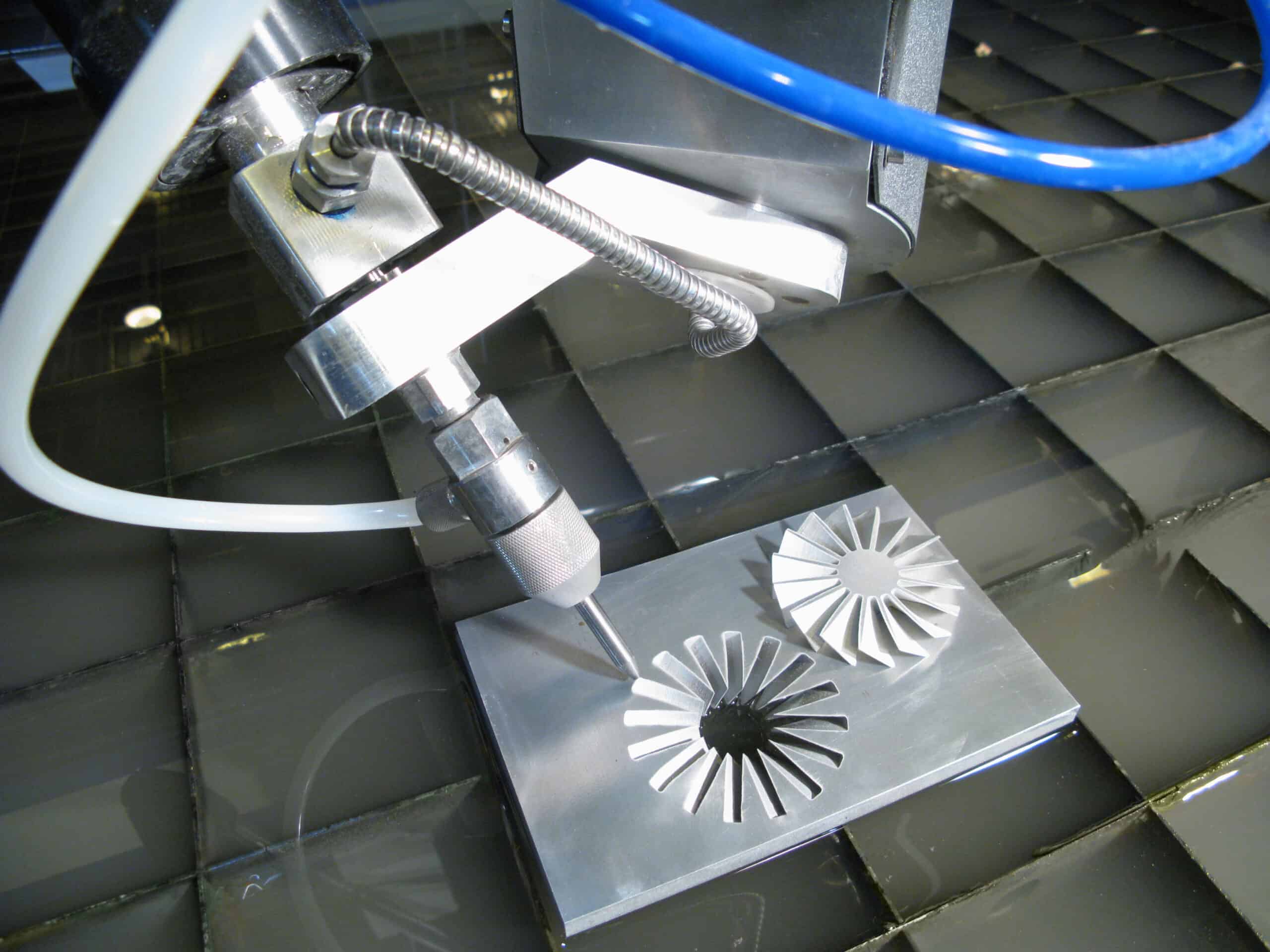

Multi-Axis CNC Milling Services

Innovative Manufacturing and Design’s 4 and 5-axis machining-centers are ready to take on any challenge and deliver a level of precision and accuracy unmatched by our competitors. Our 4 axis and 5 axis centers significantly increase the range of possibilities for working with complex surfaces and creating parts in various shapes and sizes.

The combination of our experienced CNC machinists, programmers, and wide array of equipment allow us to build a diverse range of precision parts for customers with specific challenges.

Why Choose Innovative Manufacturing and Design for CNC Machining/Milling?

Innovative Manufacturing and Design works with our clients from conception to completion providing innovative solutions that deliver exceptional products. When you work with us you can always expect:

- Open communication and collaboration with our management team and machinists

- Innovative and cost-effective solutions designed to increase productivity, save time, and money

- Streamlined processes designed to provide short lead times

- Equipped with the latest CNC mill and lathes

- ISO 9001:2015 and ITAR compliant

- 4-Axis and 5-Axis capabilities

FAQs

Custom CNC machining is a process that involves creating one-of-a-kind parts and components for various sectors such as the agricultural, automotive, and aerospace industries.

Turning is as a machining process where bars of metal are rotated while a tool is used to remove excess material until the desired shape is reached.

CNC milling (Computer Numerical Control Milling) is a machining process which utilizes computerized controls and rotating cutting tools to remove material from the workpiece to produce a specific product or part. This process is suitable for machining a wide range of materials, such as metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products.

4-axis machining adds movement of the cutting tool and allowing rotation around the X axis. As a result, there are 4 axes X, Y, Z and A rotating around the X axis. The majority of 4 axis CNC machine tools allow the workpiece to rotate, which is called b-axis, so the machine can act as both milling machine and lathe.

5-axis machines rely on a tool that moves in five different axes, the X, Y, and Z, as well as A and B, around which the tool rotates. Using a 5-axis CNC machine lets operators approach a workpiece all directions in a single operation without having to adjust the part.